Pipelines are supposed to be ideally shaped when they are commissioned: precisely round cross-section, straight pipe joints, no unexpected diameter reductions. However, even newly laid pipelines may already have defects, such as dents and wrinkles. Pipelines are often damaged by construction equipment before commissioning. Further, during their operation, pipelines may be subject to extensive stresses resulting in development of ovalities and combination of dents and corrosion. These defects are normally not critical for pipeline integrity, but some of them may lead to occurrence to a more significant threats such as cracking in dent area developing under dynamic stress. Geometry defects may also be an obstacle for pigging operations. Thus, such pipeline flaws shall not be underestimated.

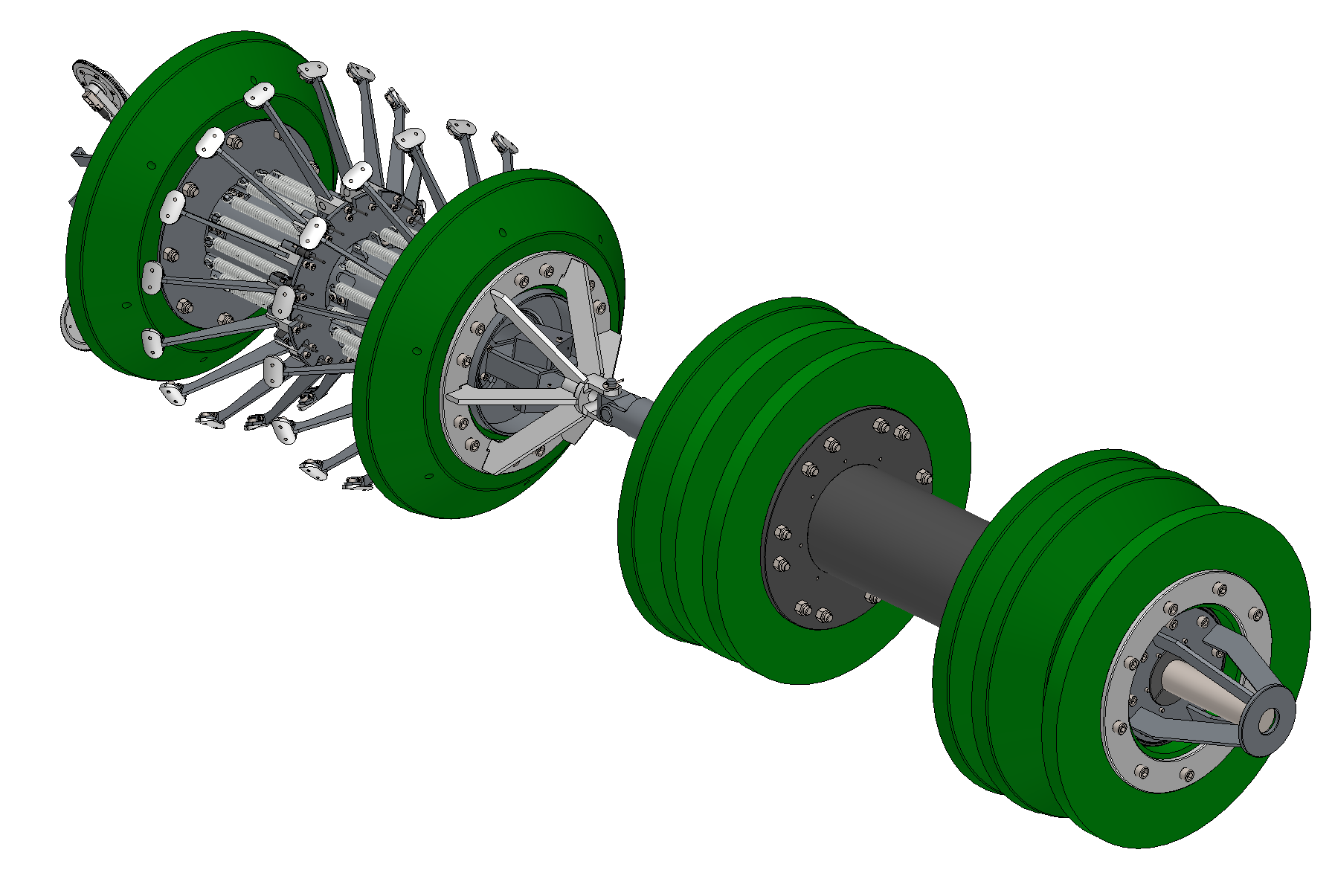

We offer geometry inspection services on pipelines with nominal size from 8” to 24”. Our multichannel geometry inspection pigs (so-called calipers) are based on the direct mechanical measurement principle – caliper arms are installed on the circumference of the pig and each one performs independent measurement. Thus, any deviation of pipeline internal diameter changes the position of a caliper arm adjacent to pipe wall which is measured and recorded by the geometry inspection pig.

LINDA’s tools are capable of detecting and measuring wide variety of pipeline geometry defects and we reliably identify them in accordance with recommendations of POF. Weld protrusions and all girth welds, ID reductions of any kind, dents, wrinkles, ovalities – we will provide a complete database on the geometry flaws in your pipeline. Moreover, if we run our geometry pig coupled with XYZ mapping unit – we will provide a comprehensive map of pipeline geometry profile directly referred to GPS coordinates including altitude.

Performance specifications of our caliper tools are:

For ovalities:

- Internal diameter reduction, accuracy 1% of pipeline ID with certainty = 90%

- Length, accuracy 10% of pipeline ID with certainty = 90%.

For dents:

- Depth, accuracy 1% of pipeline ID with certainty = 90%

- Length, accuracy 10% pipeline ID with certainty = 90%

- Width, accuracy 10% pipeline ID with certainty = 90%.